Yer man Michael Phoenix (@mphoenixuk) asks a question about binding options. It’s a good question. I like it. I’m gonna talk about it.

For the purposes of commercial comic printing there are three main types of binding. They are, in order of the order I wrote them down in:

- Saddle Stitched

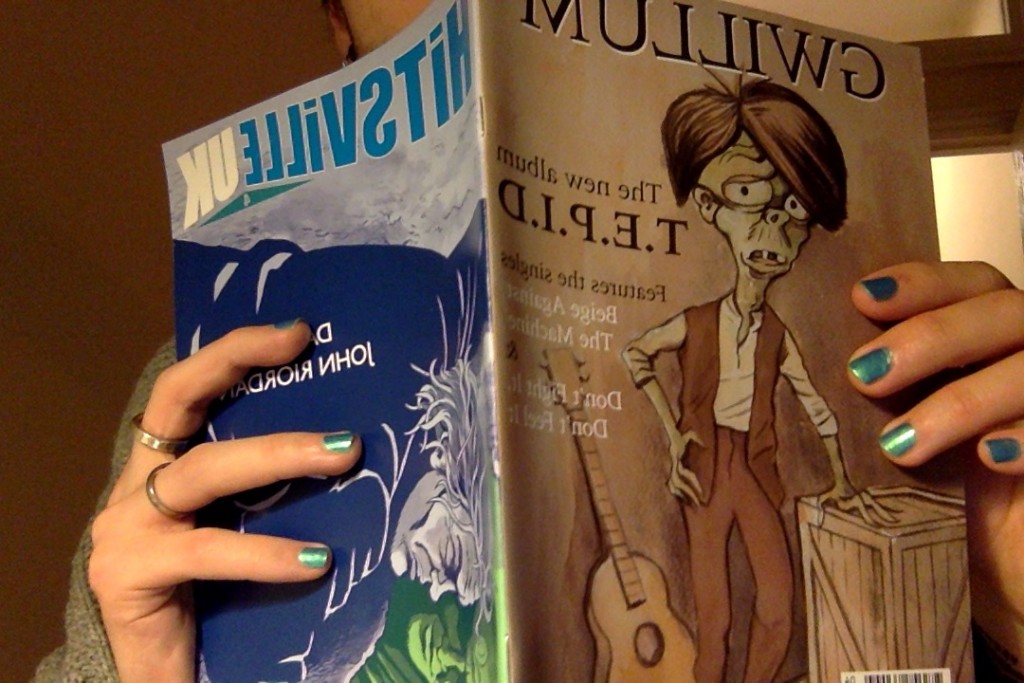

Hitsville UK, by John Riordan and Dan Cox (who doesn’t appear to have a twitter, which I am suspicious of.) - Perfect Bound

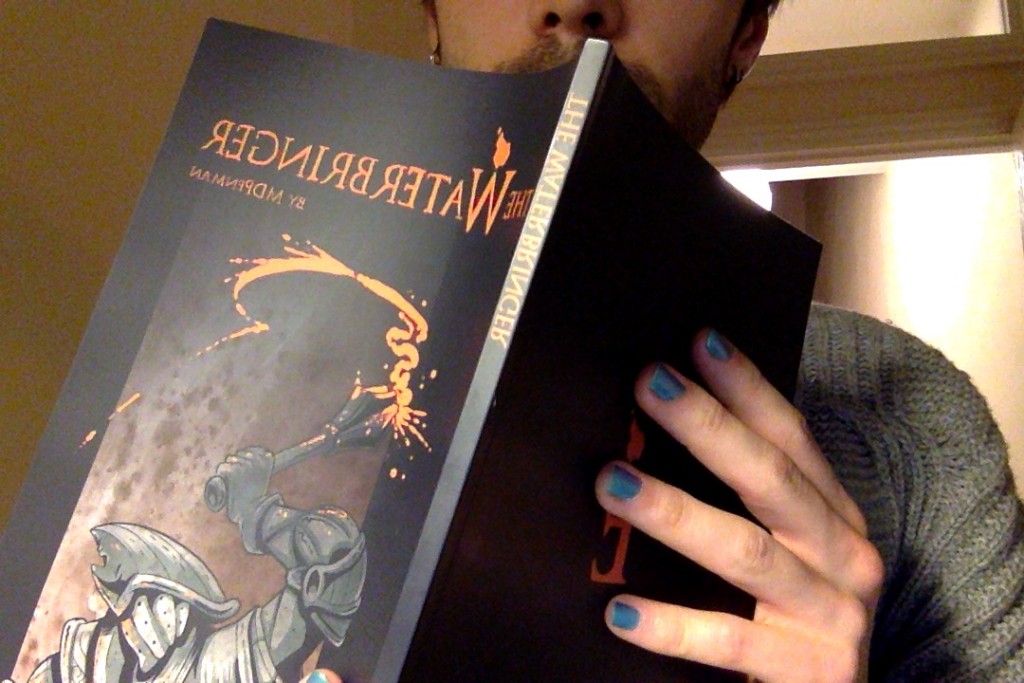

The Waterbringer, by MD Penman - Hardback

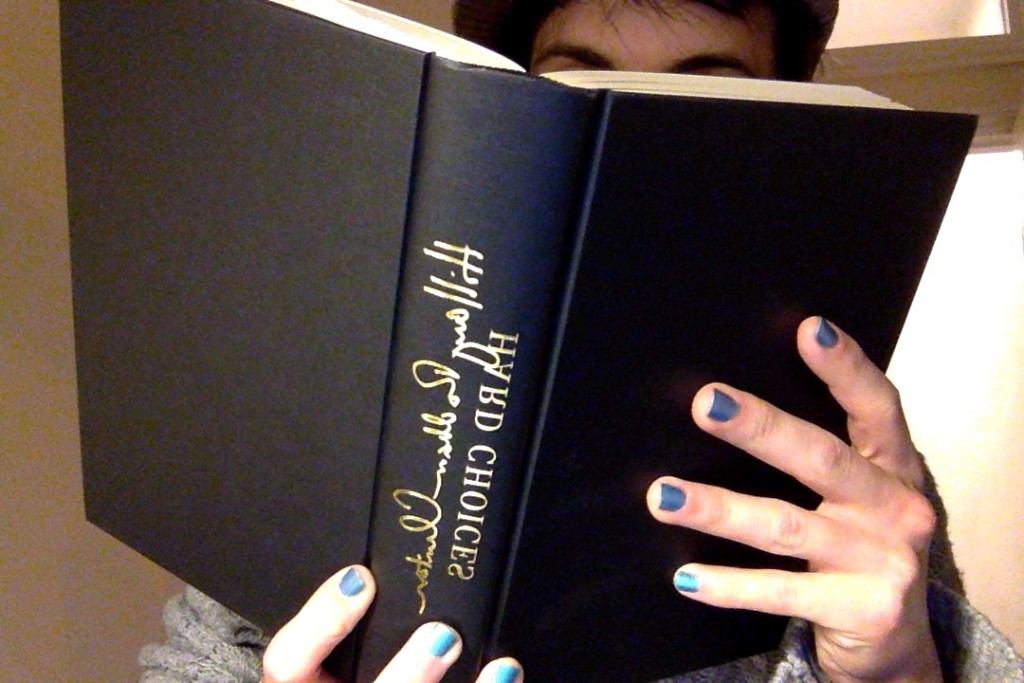

Hard Choices, by Hillary Rodham Clinton

Look, full disclaimer: I only printed two out of these three examples.

There’s a bit of a breakdown within classes, but these are the headliners. So what about them?

Saddle Stitched

Stitching is the most basic binding going. It’s staples. We call it stitching because we like to confuse you. We also call the staples themselves “wires”. We’re a fun bunch, printers are.

Good for:

- Page counts up to about 48pp inc cover.

- One shots or ongoing series.

- Keeping costs down.

- Self cover comics.

Drawbacks:

- Page counts have to be divisible by exactly 4 (although this is best practice for all bindings, really).

- Struggles to lie flat right out of the box.

- Puts a (pretty low) ceiling on what you can acceptably charge for your comics.

Perfect Binding

Additional full disclaimer: perfect binding (or, more specifically, PUR binding) is my favourite kind of binding, and I have no intention of attempting to be unbiased.

Good for:

- Page counts of 48pp and up (although we can in some circumstances PUR bind a block of as few as 24pp).

- Collecting an entire story or arc. Giving the customer a sense of “one and done” rather than having to consider how long it’ll take for the next chapter to appear.

- Looking really cool like a book you’d buy in a shop. (I did mention the bias.)

- Lifts the ceiling you can put on your pricing. It’s more expensive than stitching, but not by a ridiculous amount. Given that you can charge 50-100% more for a perfect bound book than its stitched equivalent it’s always worth considering.

Drawbacks:

- Spine clearance requirements do have a bit of an impact on your layout. Not huge, but it’s another factor to bear in mind.

- Heavy. Much, much heavier. You might not care right now, but you will when a) you’re dragging them to a con or b) you’re posting them.

- More pages = more work for you getting everything ready.

- Usually requires a laminate on the cover, which is another small additional cost. It looks nice, and it protects your covers (especially your spine) from damage in transit, but it’s a small additional cost.

PUR vs EVA

Oooh, yeah. You need to know about that. Here at CPUK (I’m trying to make the acronym a thing – have you noticed over the last few posts?) we almost exclusively use PUR binding. The major difference is the type of glue used: perfect binding uses ethylene vinyl acetate (EVA) and PUR uses polyurethane reactive (PUR) adhesive. There’s a small chance that you’re not a chemist, in which case the difference won’t be immediately clear, so let me explain.

In a standard page pull test (this is as basic as it sounds) PUR binds show up somewhere in the region of 40-60% stronger than traditional perfect binds, even though they use less adhesive for binding. That means that if you have a book that’s intended for multiple readings (perhaps, to pluck a random example from the air, a graphic novel) a PUR binding is far, far less likely to fall apart over time. It’s also far more resistant to spinal cracking when opened out flat for reading/sketching inside.

Another advantage of PUR over traditional perfect binding is that it lies flatter. Since the adhesive is so much stronger we need to use less of it, which means it allows for a more compact spine (this is also why we can bind smaller book blocks).

Traditional perfect binding has some advantages over PUR, so it’s not one to completely discard. It’s a bit cheaper, which is handy. It can also be applied to thinner coated papers, which is why you’ll often see it used on glossy mags in the shops. EVA binding also allows for a looser bind, which means you don’t need so much clearance from the spine. PUR binding is very tight indeed right out of the box, which can make a book feel quite stiff when you’re first looking at it. Of course the flipside of that is durability – it’s all well and good being able to flatten out your books on a table for display at a con, but if it breaks the spine then you’ll get pages falling out as people read. I’m told that people don’t like that.

If you’re perfect binding we’ll generally make the decision between EVA and PUR for you (personally I use the term “perfect binding” pretty much interchangeably). If you have a strong preference for EVA over PUR do mention this, because as I say we’ll usually default to PUR.

Hardback

Hardback books are serious business. The benefits are obvious, so I’ll skip those, because there are some not insignificant drawbacks…

- Setting these up is a pretty complex process. To give you an example, here’s the cover template for Mike Garley’s forthcoming collection of The Kill Screen.

- Hardbacks are phenomenally expensive to produce. The risks are high, because you’re going to need to charge a premium for them. This is very much a thing you’ll want to kickstart, because if you haven’t established demand in advance you’re at a huge risk of being left horribly out of pocket.

- Production times are longer than on other bindings. Not hugely longer, but you want to watch out for that – especially if you’re a regular customer and used to quick turnovers. (Side note, because of the non-comics work done on the side, Christmas is a terrible time of year to order a hardback. The casing machine is pretty much perpetually in use making those daft little photo gift books you see advertised on facebook and the like. Pays the bills, innit?)

- Because of the complexity of the work, we tend to produce these only in short run batches. There’s a ceiling of about 500, which means you’ll be dealing with a hefty per unit price.

All that being said, hardbacks do look really, really cool. And if you’ve established the market beforehand they’re a great addition to your offering for hardcore fans. Just… maybe allow more time than usual in these projects for back and forth on files, unforeseen setbacks and the like…

That’ll about wrap us up for today. As ever, if you have any questions drop an email and we’ll do our best to answer them. Thanks again to Michael for suggesting the post.

Hello there,

What are your thoughts on spiral binding? I finished a comic book recently and have also designed an animated lenticular of around 8 frames for the cover/sleeve which I would like to cover the book with, in order for it to have a spine to put the title on:

http://www.designersinsights.com/designer-resources/choosing-the-right-binding-type

I know that these are usually left for manuals/text/cookbooks etc, but I was thinking of having 3 -5 more lenticular within the book itself if I can afford it*.

Spiral bound would probably be best for something like this due to the sheets thickness.

*If I cant, then it’s no biggie. I’ll just stick to the flat version.

Hello to you too,

In principle it’s a good thing. Pretty unusual look, which helps you stand out. You’re going to need a pretty hefty chunk of pages to balance the binding and make it look right, but that’s not beyond the ken of man.

The problem you’re going to have is getting those covers printed, as that can’t be done on a regular press (the rigid plastic won’t get through). It’s not impossible, but you’re looking at a specialised process that a lot of printers (ourselves included) won’t do in house, which is going to drive the costs up.

When we do manuals like this we leave the plastic covers unprinted, or in some cases frosted/half frosted, with a printed card cover underlay. This works well for that kind of thing, but it doesn’t really seem like it’s going to work for what you’re after here. Ping over an email with an example of your artwork and we’ll have a look – even if we can’t do it ourselves we might be able to point you in a helpful direction!

Cheers

CPUK

Thank you very much for the reply.

I sent an example off to you.